Major Automakers Embrace Tesla’s Innovative Manufacturing Method

Major Automakers Embrace Tesla’s Innovative Manufacturing Method

Can giga-casting be the game-changer the automotive industry needs?

Tesla’s giga-casting technique has caught the attention of several automakers, including Ford, Hyundai, and Volvo. This revolutionary method has the potential to significantly streamline production processes and lower costs.

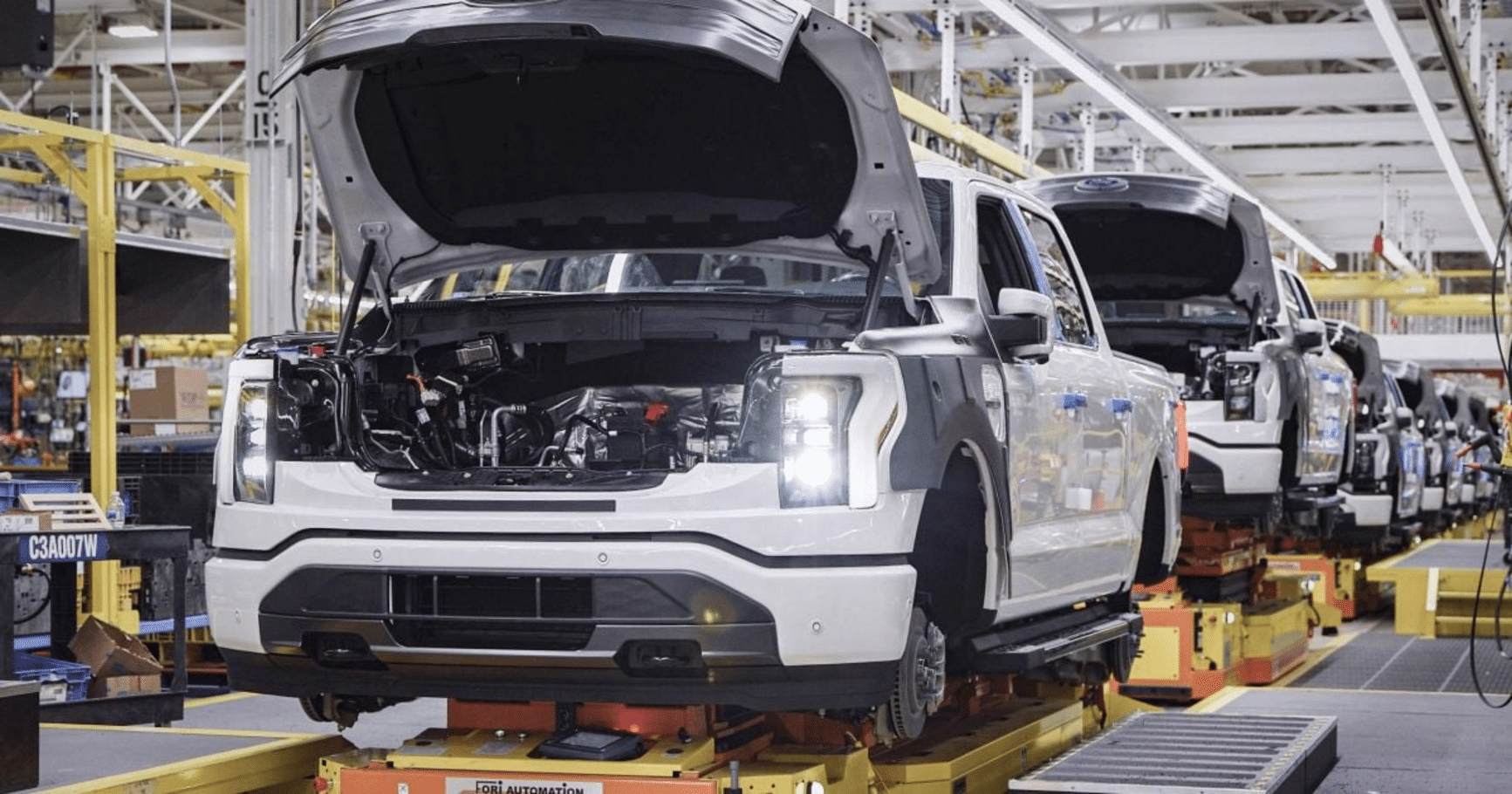

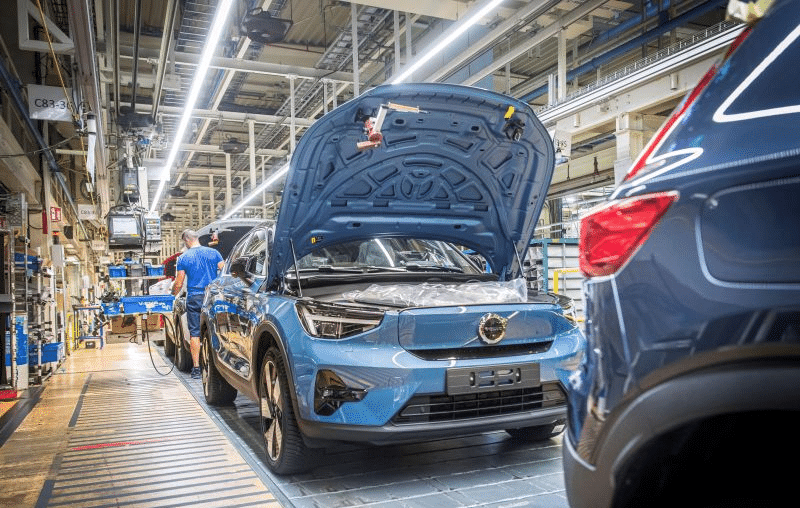

Tesla’s giga-casting technique, which involves the use of ‘giga-casting’ machines, has garnered interest from major automakers. Italian casting specialist Idra has recently added Ford, Hyundai, and an unspecified European carmaker to its customer base, with Volvo being the likely candidate. These automakers are looking to replicate the success Tesla has achieved in significantly streamlining its production process and lowering costs.

Giga-casting is an innovative production method that allows for the stamping out of larger chassis components in one operation. This eliminates the need for casting numerous smaller parts, drilling thousands of holes, and spot-welding or bonding those pieces together. Instead, giga-casting machines can create a large part of a chassis in a single press. This method is highly advantageous for mainstream automakers as it enhances production efficiency and speed, reduces production costs, and, importantly for electric cars, lowers kerb weights.

To achieve giga-casting, specialized machines press down on a unique aluminium alloyed plate. These machines can exert an incredible force of 6000 to 9000 tons to stamp out the car body. This level of force enables the production of larger and more complex components with high precision.

Recent reports indicate that Ford and Hyundai are actively testing giga-press machines. A Giga Press 6100, branded with Ford’s logo, has been spotted undergoing testing at Idra’s plant in Italy. This machine is expected to be further evaluated at a research and development facility in Detroit before being put into service. Additionally, an even larger Giga Press 9000 was reportedly being tested nearby without any branding. This machine is said to be destined for a Hyundai facility for research and development purposes.

Idra, the supplier of giga-casting machines, is on the verge of finalizing a deal with a mystery ‘premium automaker in Europe’ for two Giga Press 9000 machines. Sources suggest that Volvo is the automaker in question, as it seeks production solutions for its new plant in Eastern Europe. Idra has already received orders for 25 presses, with 21 of them already delivered to customers, including ‘tier 1’ parts manufacturers.

Tesla, being the pioneer of giga-casting, has already received 14 presses from Idra. This includes two Giga Press 9000 models that will be used in its forthcoming Cybertruck production plant in Austin, Texas.

- Italian casting specialist Idra adds Ford, Hyundai, and possibly Volvo as customers

- Giga-casting allows for the stamping out of larger chassis components in one operation

- The technique increases production efficiency, lowers costs, and reduces kerb weights

- Ford and Hyundai are testing giga-press machines before implementation

- Volvo is rumored to be the mystery European automaker signing a deal for giga-press machines

The increasing adoption of Tesla’s giga-casting technique by major automakers demonstrates its potential to revolutionize the industry. The ability to streamline production processes, lower costs, and reduce kerb weights is highly desirable in the fast-paced automotive world. As Ford, Hyundai, and Volvo test and implement giga-press machines, it will be interesting to see how this innovative manufacturing method shapes the future of car production.