General Motors Delays Production of Chevrolet Silverado EV and GMC Sierra EV Due to Shifting Demand

General Motors Delays Production of Chevrolet Silverado EV and GMC Sierra EV Due to Shifting Demand

How will General Motors navigate the changing landscape of the EV market as they strive to meet their production targets?

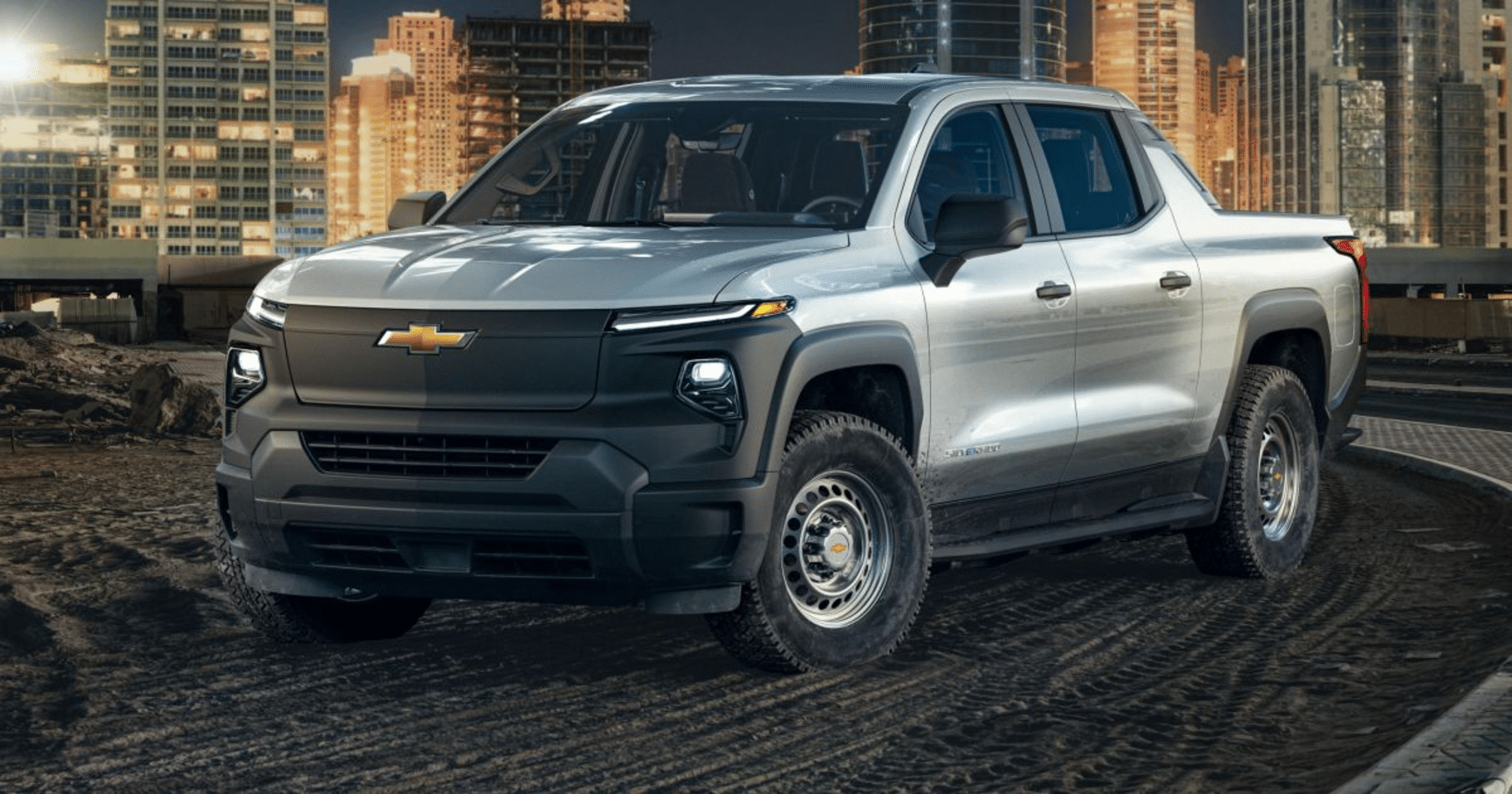

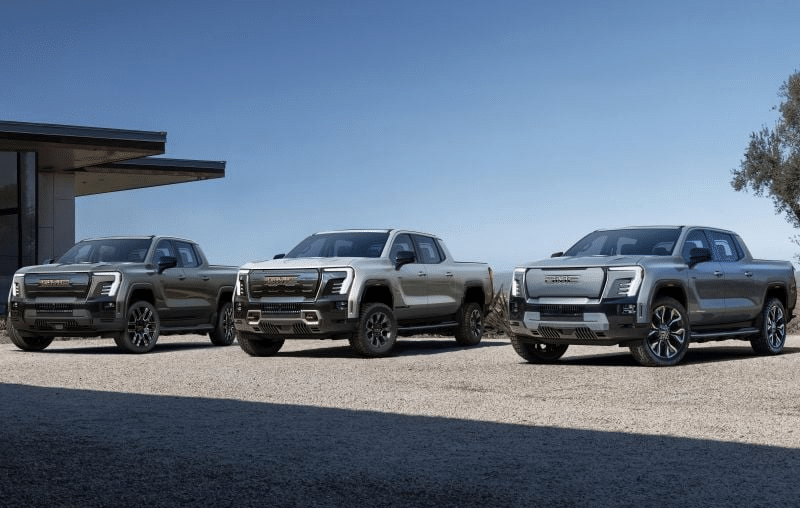

General Motors has made the decision to postpone production at its Orion Township plant in Michigan for the Chevrolet Silverado EV and GMC Sierra EV by 12 months. This delay comes as a result of changing demand for electric vehicles (EVs). While the Silverado EV is already being manufactured at GM’s Detroit-Hamtramck plant, the Sierra EV will now join it in 2024. GM cites the need to align with evolving EV demand and better manage capital investment as the reasons for this delay.

GM has attributed the delay in production for the Chevrolet Silverado EV and GMC Sierra EV at its Orion Township plant to the changing demand for EVs.

While the Silverado EV is already rolling off the line at the Detroit-Hamtramck plant, plans to also produce the two electric pickup trucks at the Orion Township plant have been pushed back to late 2024.

GM believes that this delay will allow them to better handle capital investment while aligning with the evolving demand for EVs in the market.

It is worth noting that GM’s Ultium joint venture plant in Ohio, responsible for battery production, has experienced delays due to issues with its automation equipment supplier. However, GM has clarified that this delay in Orion Township is unrelated to its battery plant plans.

Additionally, the recent strike action by the United Auto Workers union did not influence GM’s decision to delay production at the Orion Township plant.

Despite this delay, GM still intends to add a new shift at the Detroit-Hamtramck plant next year, which is also responsible for manufacturing the GMC Hummer EV.

GM has set a goal to produce a total of 400,000 EVs from 2022 to the first half of 2024. They anticipate that 100,000 of these vehicles will be produced in the second half of this year.

GM’s focus remains on scaling up its EV program. In the first half of 2023, the company delivered 36,024 EVs in the US, with only a small portion being the latest Ultium-based models such as the Cadillac Lyriq and GMC Hummer EV. The majority of the deliveries consisted of more affordable models like the Chevrolet Bolt and Bolt EUV, which will soon cease production. GM has confirmed plans to introduce a new-generation Bolt with Ultium batteries, although the timing has not been specified.

According to Reuters, the EV market in the US is experiencing growth, albeit at a slower pace. The result is an oversupply of unsold EVs on dealer lots. For example, as of June 30, Ford had 86 days’ worth of F-150 Lightnings in stock, surpassing the industry average of 52 days’ supply. The Mustang Mach-E SUV fared worse, with 113 days’ supply.

This decline in demand prompted Ford to reduce its work shift at the Rouge Electric Vehicle Center, where the F-150 Lightning is manufactured. An internal memo from a UAW leader confirmed the faltering demand for the F-150 Lightning in the US.

Despite the challenges, Ford began production of the F-150 Lightning in April 2022 after receiving approximately 200,000 orders. The company has increased the production target at the Rouge Electric Vehicle Center twice, aiming for an annual rate of 150,000 vehicles.

- GM blames evolving EV demand for delaying production at Orion Township plant by 12 months

- Silverado EV currently in production, Sierra EV to join in 2024

- Delay allows for better capital management and alignment with EV demand

- Production at Ultium battery plant and UAW strike not affected

- GM plans to have 400,000 EVs built by mid-2024

The shifting demand for EVs has prompted General Motors to delay production of the Chevrolet Silverado EV and GMC Sierra EV at its Orion Township plant. However, GM remains committed to its goal of producing 400,000 EVs by the first half of 2024. As the EV market continues to evolve, automakers are adjusting their strategies to meet changing consumer preferences and maximize capital investment.