Daihatsu Halts Production as Safety Scandal Unfolds

Daihatsu Halts Production as Safety Scandal Unfolds

Will Daihatsu be able to restore trust and rebuild its reputation in the wake of this safety scandal?

The Japanese small car specialist, Daihatsu, has been hit with a major blow as its production lines come to a standstill due to a government investigation into years of falsified safety results. With admissions of improper testing and data falsification across 64 models, including some dating back three decades, the repercussions of these closures are expected to have a significant impact on Japan’s economy. Let’s dive into the details.

The recent scandal surrounding Daihatsu has caused the Japanese brand to halt production at all four of its factories. The reason? Improper testing of 64 models, some of which goes back over 30 years. This admission has resulted in the closure of domestic vehicle shipments and exports outside of Japan.

The impact of these closures is expected to be significant, not only for Daihatsu but also for Japan’s economy at large. According to market research by Teikoku Databank, Daihatsu’s factory supply chains involve a staggering 8136 companies across the country, with sales totaling 2.2 trillion yen ($22.6 billion). The ripple effect of this shutdown will be felt by businesses throughout Japan.

Further investigations by Daihatsu have revealed even more cases of irregularities in safety tests and procedures. A total of 174 new instances have been found across 25 testing categories, on top of the already known issues. This misconduct stretches all the way back to 1989 and includes falsification of data and unauthorized test procedures.

Daihatsu President, Soichiro Okudaira, has acknowledged the company’s wrongdoing in safety tests and procedures. He equated this conduct to neglecting safety certification entirely, further emphasizing the severity of the situation. Okudaira attributed the misconduct to the increasing pressure placed on workers to meet ambitious demands and tight development deadlines.

In response to these revelations, Daihatsu issued a media statement expressing deep apologies for the inconveniences caused to customers and stakeholders. The company also emphasized its commitment to rectifying the situation and preventing any future recurrences. To achieve this, Daihatsu has requested an independent third-party committee to thoroughly investigate the irregularities, determine their causes, and recommend preventive measures.

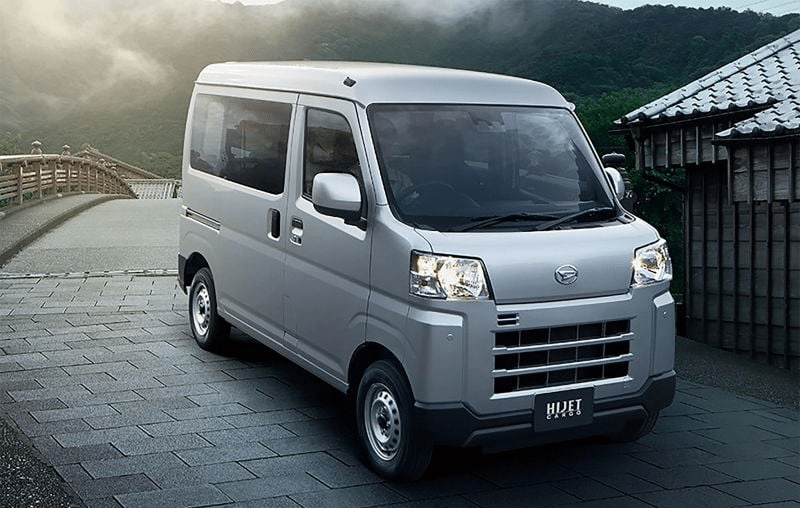

Although Daihatsu no longer operates in the Australian market, it remains a significant vehicle manufacturer in Japan. Popular models such as the compact Hijet trucks and vans, as well as the Mira passenger vehicles, have solidified Daihatsu’s presence in the country. While the company has not provided a timeline for the resumption of operations, Japanese media reports suggest that production may remain suspended until at least January.

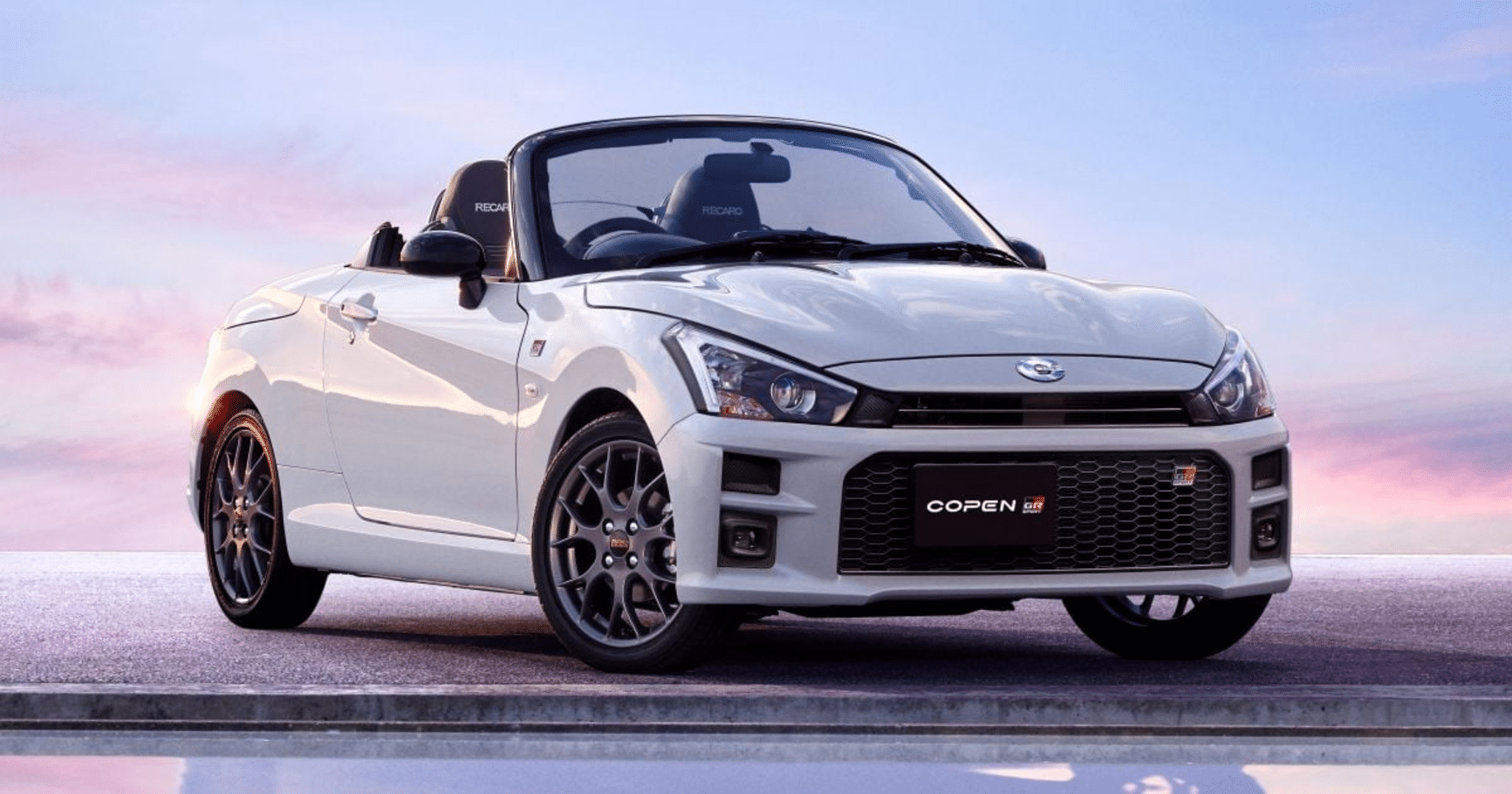

The recent revelations surrounding Daihatsu’s safety scandal raise questions about its future plans. The company had unveiled a range of concepts at this year’s Japan Mobility Show, including the Vision Copen Concept, which hinted at a potential new iteration of the iconic Japanese sports car. Additionally, Daihatsu announced its collaboration with Toyota in developing compact electric vehicles. The Uniform Cargo and Truck concepts showcased at the event are likely to be zero-emissions replacements for Daihatsu’s existing commercial vehicles.

One particular concept, the Daihatsu Osanpo, stands out as a high-riding electric convertible designed for leisurely enjoyment of nature. Its description as ‘a luxurious vehicle to slowly enjoy the nature around you in a pleasant breeze, as if taking a walk’ paints a vivid picture of its purpose.

Looking ahead, Daihatsu’s partnership with Toyota and Suzuki in the development of kei-class electric vans shows promise for the future. These electric vans, expected to be available in 2023, aim to leverage the manufacturing expertise of Daihatsu and Suzuki with Toyota’s electrification technology. Kei-class vans make up a significant portion of Japan’s commercial vehicle fleet, particularly in last-mile logistics.

Despite the potential, electrifying the kei segment poses challenges. Higher purchase prices, costs associated with charging infrastructure, and the inconvenience of charging downtime are among the major obstacles highlighted in Toyota’s announcement. The industry will be watching closely as Daihatsu navigates its way through this safety scandal and continues to shape the future of Japan’s automotive landscape.

- Daihatsu has shut down production at all four of its factories due to improper testing of 64 models

- Domestic vehicle shipments and exports have also been suspended

- The closure will affect Japan’s economy, with 8136 companies in the supply chain

- 174 new cases of irregularities have been found in safety tests and procedures

- The misconduct dates back to 1989 and has been attributed to pressure on workers

Daihatsu’s safety scandal has taken a toll on the company, leading to the suspension of production, domestic shipments, and exports. The wide-reaching impact of these closures on Japan’s economy cannot be ignored. As investigations continue and Daihatsu aims to rectify its procedures, the question arises: can the company regain the trust of its stakeholders and emerge stronger from this crisis?