Nissan Urges Australian Government to Streamline Car Homologation Process

Nissan Urges Australian Government to Streamline Car Homologation Process

Why should car manufacturers face extensive delays and increased costs due to the Australian homologation process?

The process of homologating cars for the Australian market has caused significant delays and increased costs for car manufacturers. Nissan is the latest brand calling on the government to find a better solution to these challenges.

Francois Bailly, Nissan’s senior vice president of region and chief planning officer, has raised concerns about the process of homologating cars for the Australian market. He emphasizes that the time frames and requirements for local homologation make it difficult to bring vehicles to Australia.

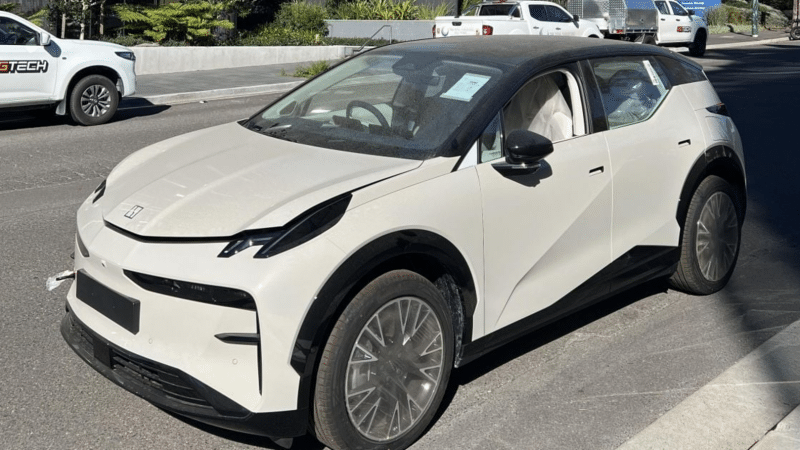

The introduction of Nissan’s first electric SUV, the Ariya, has faced repeated delays due to the need for top-tether child seat anchors which are specific to Australia. These anchors are not required in Europe, Japan, or the United States. The engineering challenge posed by the small size of the Australian market makes the process costly without any benefit to the customer.

Mr Bailly highlights the lengthy period it takes for a car that already exists in Europe and Japan to be homologated to Australia, which is approximately 45 weeks. He points out that this is especially problematic considering the new fuel efficiency standards and CAFE regulation that have given manufacturers a short timeframe for new model introduction without assisting them in meeting homologation requirements.

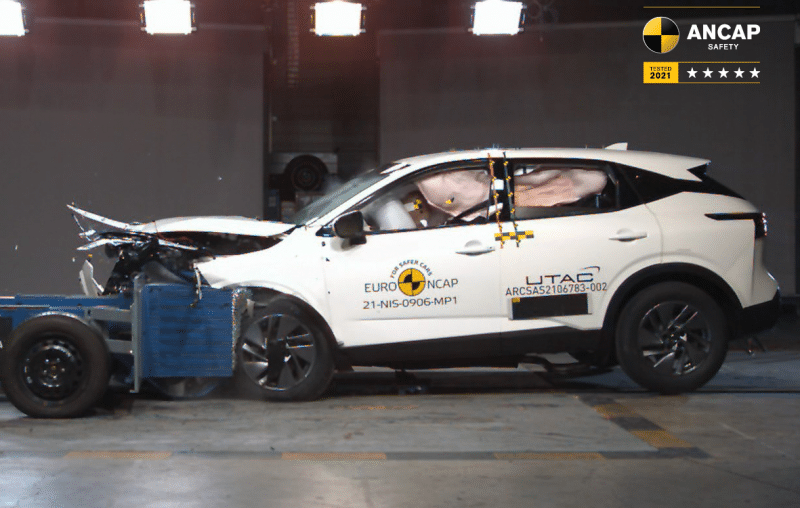

In order to reduce costs and speed up the homologation process, Mr Bailly suggests aligning Australia’s design rules and safety testing requirements with those of larger markets such as Europe, Japan, or North America. As Australia is a fully import market, he argues that it would make more sense to align with these markets rather than modifying cars for Australian Design Rules.

Nissan is not alone in its call for the government to streamline the car homologation process. Many manufacturers have been urging the government for years to align automotive design rules and safety testing with larger markets, in order to reduce costs for engineering cars for the relatively small Australian market.

- Nissan’s senior vice president expresses frustration with the time and requirements of local homologation for bringing vehicles to Australia.

- The introduction of Nissan’s first electric SUV, the Ariya, has been delayed due to the need for specific child seat anchors required in Australia.

- The small size of the Australian market makes this engineering challenge costly and without benefit for customers.

- The government is urged to align design rules and safety testing requirements with bigger markets to reduce costs and speed up the homologation process.

In conclusion, Nissan’s senior vice president has expressed frustration with the challenges posed by the current homologation process in Australia. The need for specific child seat anchors required in Australia has caused delays for the introduction of Nissan’s first electric SUV. Nissan, along with other manufacturers, urges the government to align design rules and safety testing requirements with bigger markets to reduce costs and speed up the homologation process.